Service

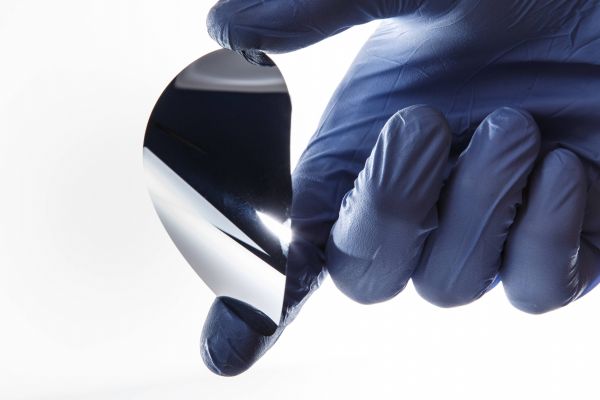

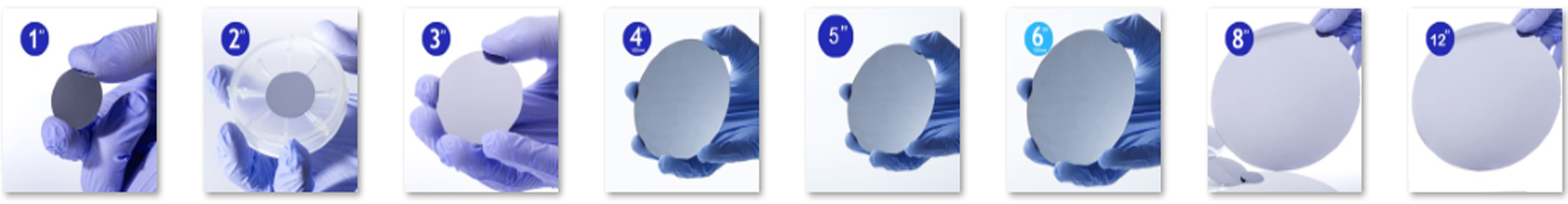

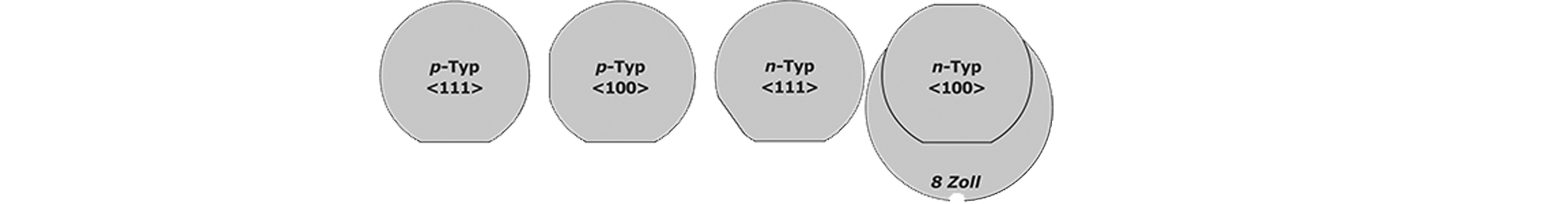

We offers Prime and Test silicon wafers that adhere to SEMI standards in a variety of diameters from 1″ to 12″ (300mm). In addition to SEMI Standard silicon wafers, we offer (FZ) float zone wafers, (SOI) silicon on insulator wafers, and other semiconductor materials. Double side polished, oxide, MEMS wafers are also available.

We also provides silicon thermal oxide wafers SIO2 with many thermal oxide options, including wet, dry, and hybrid growth; and thicknesses from 150Å up to 150,000Å.

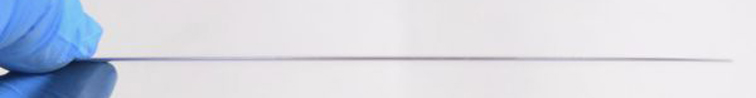

We understands the need for top level purity and thus offers superior Float Zone Silicon technology to the growing needs of its clients. The world’s need for highly efficient products can only be met by super pure Float Zone (FZ) Wafers, and rest assured as this is exactly what we have to offer.

Float Zone Silicon is extremely pure silicon that serves as an alternative to crystals obtained from the previously used Czochralski process. Float Zone Wafers do not have any baggage when compared to wafers made from Czochralski’s method and offers a great number of advantages that makes it ideal for applications such as solar chips, RF circuits and accurate power devices. FZ silicon has a very low concentration of oxygen and carbon impurities however its mechanical strength is improved by deliberately adding nitrogen to it. Well suited for applications where clock cycles in the order of tera are required, FZ Silicon Wafers are ideal for use in power devices and sensors.

Types of FZ Wafer

Similar to our policy with SOI wafers, FZ wafers are offered with great customizability and the parameters are greatly flexible as per your needs.

For FZ wafers, JINGXIN ELECTRONICS offers diameters of 2, 3, 4, 5, 6 and 8 inches using methods:

FZ

NTD FZ

GD FZ

We offer Float Zone Wafers with resistivity ranging in between 1 – 100000+ Ohms/cm, therefore, there is very little chance that we don’t pack what your produce requires.

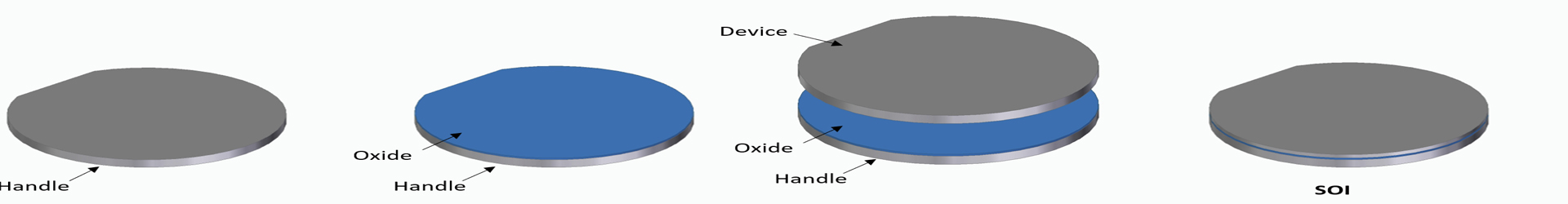

Customizability is a major cornerstone of JINGXIN ELECTRONICS and we always try our best to meet all your needs. In that very essence JINGXIN ELECTRONICS offers SOI wafers of the following types:

Thick SOI Wafers

Ultra-Thin SOI Wafers

Ultra-Uniform SOI Wafers

Ultra-Flat SOI Wafers

JINGXIN ELECTRONICS provides high quality silicon thermal oxide wafers in all diameters from 2″ to 300mm. We ensure your specific requirements are met by choosing prime grade and defecting free silicon wafer as a substrate so that a high uniform layer of thermal oxide is formed in a furnace.

In micro-technology, the main insulating material used is Silicon dioxide which in chemical symbols is written as SiO2. In order to produce an insulating oxide layer, thermal oxidation, which is the most common technique used to obtain the layer is used. The process of obtaining the layer is performed in a furnace.

Any amount of quantity can be ordered with a minimum batch order of 25 wafers.

Types of Thermal Oxidation

1. Dry oxidation

Silicon reacts with oxygen leading to a moving interface towards the substrate. Dry oxidation is carried out under temperatures of between 850 and 1200°C and demonstrates low growth rates. This leads to the production of a high quality oxide for MOS gate insulation. In cases where highest quality thin silicon oxide layer is required, then dry oxidation is the preferred method to wet oxidation.

Our capability: Dry thermal oxide from 15 to 300 nm

2. Wet oxidation

In this method, a mixture of hydrogen and a high-purity oxygen are burned at ~1000°C leading to the production of water vapour. Although this method may not produce a very high quality end product and may only be used as a masking layer, it is advantageous in the way it produces a higher growth rate than the dry oxidation.

Our capability: Wet thermal oxide from 50 nm to 15 µm,

WE not only provides silicon wafers, FZ wafers, SOI wafers, but also some other semiconductor materials.

Suc as Wafer Pckage....

Service

Contact Us

Name: Sales Manager

Tel: +86-13957011050

E-mail: [email protected]

QQ: 23285138

WeChat: siwafer

Add: NO.1 Buliding TaoXi Road ChengGuan Town ,KaiHua County,QuZhou City,ZheJiang Province

Mail inquiry

Mail inquiry QQ online

QQ online